Advancing Segmental Bridge Technology

Analysis and optimization of post-tensioned precast concrete bridge segments

Precasting details simplified

Faster erection and improved durability

Finley Engineering Group, Inc. (FEG) of Florida is providing final design and construction engineering services for six segmental bridges on Israel Road 431 project – the first in Israeli bridge construction history to use external tendons. FEG used LUSAS Bridge to analyse and optimize the pier and deviator segment diaphragms for the imposed loadings whilst keeping the segment weight within the 65 tonne lifting capacity of the contractor equipment. As a result of FEG design the owner and contractor were provided with major benefits from simplified precasting details, thinner sections, rapid erection procedures and improved long-term durability..

Overview

Israel has constructed more than 25 segmental bridge structures in the last 20 years. But despite the country considerable experience with segmental bridges, the six FEG-designed bridges for one of the interchanges on the 21km long, Design-Build-Operate-Transfer venture will be the first in Israeli bridge construction history to use external tendons. These 12.5m wide bridges have span lengths ranging from 30m to 66m and consist of 501 precast segments with a total deck area of more than 18,000 square metres.

Road 431 Project, Israel

Road 431 is one of the lateral access roads to the Cross Israel Highway (Highway 6) and actually constitutes the southern traffic artery of the ring orad surrounding the Greater Tel Aviv Metropolitan Area (Gush Dan), consisting of Ayalon Highway in the West, Highway 6 in the East and Road 531 in the North.

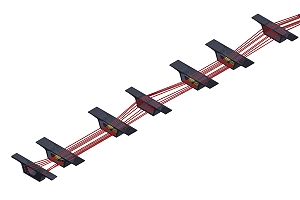

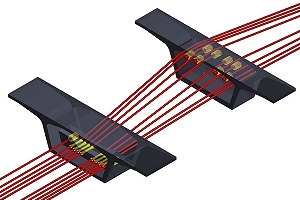

Schematic of end, deviator and pier segments showing the external tendon arrangement

Schematic of a deviator and a pier segment showing tendon arrangement

The design process included a technical review by Israeli General Consultant engineers to confirm that the external tendon system adequately met the project requirements. To assist the Israeli engineers in evaluating external tendon post-tensioning systems, FEG produced a technical white paper that included details of previous projects, excerpts from technical articles, and a list of benefits that the external tendons bring to the project. It also included FEG analysis of tendon loss scenarios to meet strict bridge security requirements and design methodology for service and ultimate limit state design with external tendons.

External tendon benefits

The use of external tendons also provided technical advantages in the bridge design, such as increased ductility for flexural moment resistance and a significant reduction in principle tensile stresses in the box girder webs. These benefits allowed for longer, constant-depth span lengths for the bridges while still meeting the interchange design requirements. “The large anchorage zones required for external tendons presented a challenge in keeping the pier segment weight within the 65 tonne lifting capacity of the contractor equipment “, said Craig Finley, President of Finley Engineering Group, “but by using LUSAS we easily modified complex shapes and efficiently optimized the internal pier segment dimensions”.

Along with the introduction of external tendons, FEG incorporated several other innovations on this project, including the use of diabolos in the pier segments and deviators to simplify the external tendon details. These post-tensioning details allow for replacement of the external tendons should this be required in the future. FEG also specified the use of pre-packaged grouts, multiple levels of protection and enhanced duct systems to improve post-tensioning system performance.

Deviator segment model